Make it Mighty

At MITO® Material Solutions, we believe material improvements are life improvements. As a next-generation company, we solve the manufacturing industry’s biggest challenges with micro-sized solutions—and make high-performing materials easy to use and accessible to all.

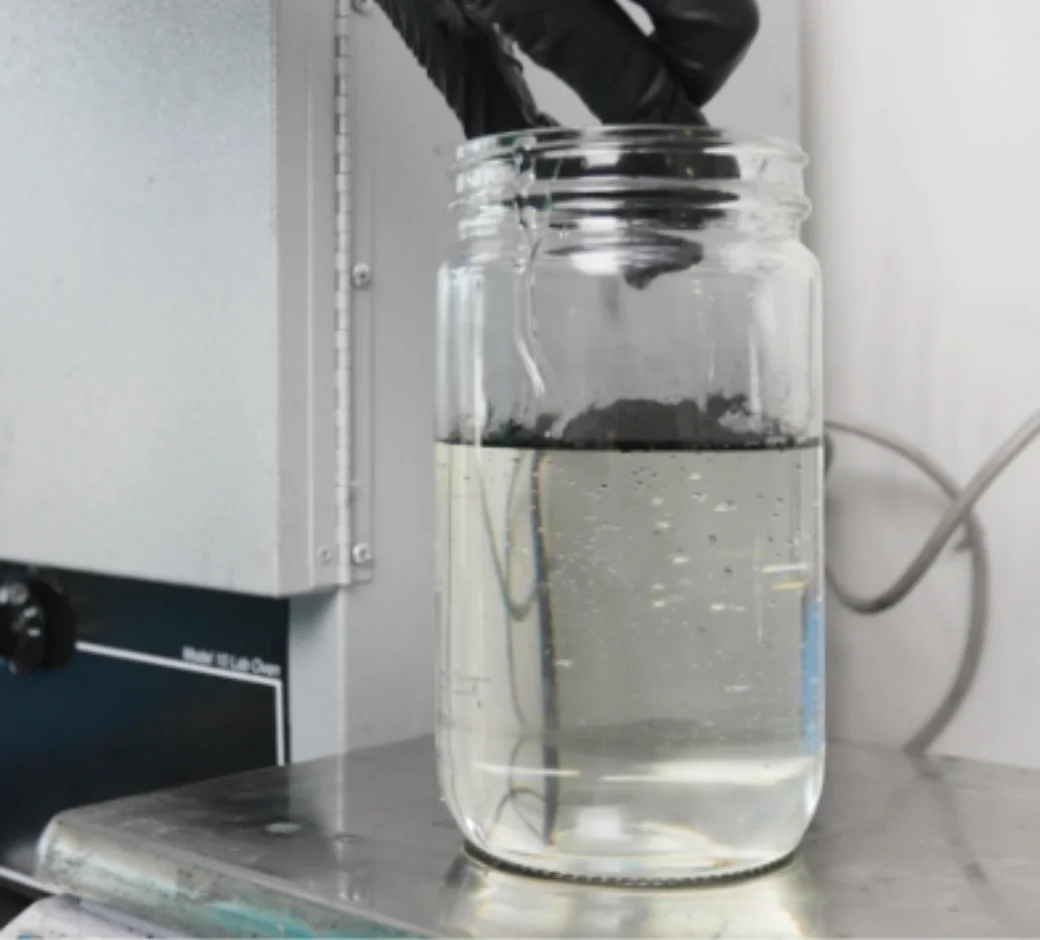

The key is the hybrid additive. Our patented platform technology is the first and only process with the power to functionalize substances like graphene oxide and biomaterials—creating hybrid additives that give fiber-reinforced composites and thermoplastics lab-verified improvements in strength, durability, flexibility, and sustainability.

Our platform technology solves your biggest manufacturing puzzles without changing your manufacturing process. It’s seamless, scalable, and adaptable, with limitless engineering applications.

But at MITO, innovation doesn’t just live in a laboratory. Our technologies solve a wide variety of real-world problems, and so do our people. We’re nimble. We’re adaptive. We’re accessible. We’re passionate. We face challenges head-on and work with partners one-on-one. You might say we’re a little different, and we like it that way.

Where some see obstacles, we see opportunities. While others choose to keep ideas under lock and key, we share ours with the world. And rather than accepting limitations, we test, challenge, and bend them—to build solutions that break every rule in the book, for the better.

Because at MITO, we believe optimism isn’t a feeling. It’s an intentional act. It’s imagining a brighter future and working hard to make it a reality—and it’s at the core of every product we create, every process we develop, and every partnership we build.

We changed the rules, so you could change the game. And together, we’re redefining what’s possible.